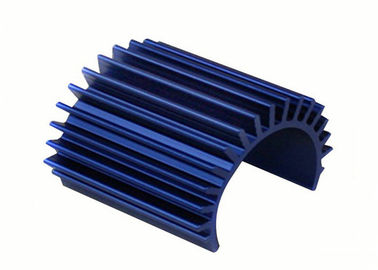

Industrial LED Aluminium Heat Sink Profiles Colourful High Efficiency Enclosure

About Xinyu Aluminum:

1. Founded in 1993, 23 years manufacturing experience;

2. USD 3,300,000 registered capital, 5 factories and 5000 employees;

3. ISO9001: 2008, ISO14001: 2004, SGS, AA grade standardize corporate.

|

Detailed Descriptions (Payment Terms/Shipment Terms/Lead time/Min. Order):

|

|

Name

|

aluminum heat sink enclosure from direct factory |

|

Biggest width

|

600MM

|

|

Process

|

CNC milling and turning, drilling, grinding, bending, stamping, tapping

|

|

Tolerance

|

0.05mm~0.1mm

|

|

DRW format

|

PDF/DWG/IGS/STP/ etc

|

|

Equipment

|

CNC machining center, CNC turning, General milling machines.

|

|

Capacity:

|

10,0000pieces per month

|

|

MOQ:

|

10pcs

|

|

Machining Scope:

|

1). Equipment/Machinery

2). Medical & Technological parts

3). The Automotive/motorcycle parts

4). The telecommunication parts

5). The power tool parts

6). Bicycle parts

7). The agricultural parts

8). Hardware

|

|

QC System:

|

100% inspection before shipment

|

|

Payment term

|

T/T , West Union,FOB,L/C

|

|

Surface treatment

|

Anodizing, zinc/chrome/nickel/silver/gold Plating, Polish, Imitation, , Heat treatment etc

|

|

Shipment Terms:

|

1) 0-100kg: air freight priority

|

|

|

2) >100kg: sea freight priority

|

|

|

3) As per customized specifications

|

|

Packing

|

1. Prevent from damage.

2. As customers' requirements, in perfect condition.

3. Send the sample by express, 3~5 days door to door service.

|

|

Note:

|

All parts are not in stock, custom made according to customer's drawings or samples!

If you have any parts to be made, please feel free to send your kind drawings.

|

|

Aluminium Alloy Chemical Composition

|

|

Alloy

|

6063 (%)

|

6063A (%)

|

6061 (%)

|

6082 (%)

|

|

Si

|

0.2~0.60

|

0.3~0.60

|

0.4~0.80

|

0.7~1.30

|

|

Fe

|

0.35

|

0.15~0.35

|

0.70

|

0.50

|

|

Cu

|

0.10

|

0.10

|

0.15~0.40

|

0.10

|

|

Mn

|

0.10

|

0.15

|

0.15

|

0.40~1.0

|

|

Mg

|

0.45~0.90

|

0.60~0.90

|

0.80~1.20

|

0.6~1.20

|

|

Cr

|

0.10

|

0.05

|

0.04~0.35

|

0.25

|

|

Zn

|

0.10

|

0.15

|

0.25

|

0.20

|

|

Ti

|

0.10

|

0.10

|

0.15

|

0.10

|

|

Other (each)

|

0.05

|

0.05

|

0.05

|

0.50

|

|

Other (total)

|

0.15

|

0.15

|

0.15

|

0.15

|

|

Al

|

Remainder

|

Remainder

|

Remainder

|

Remainder

|

All kinds of surface treatment

|

Mill finish

|

Finish of aluminum itself, with a natural anodic layer formed in the air, weak corrosion resistance.

|

|

Shine metal sliver

|

|

Anodizing

|

Through an eletrical process to form a certain layer of anodic layer on the surface of profile.

|

|

available in different colors like metal silver, champagne, darkbronze, black, and the same color with mette effect.

|

electrophoresis

|

Base on anodized process, an extra transparent film is formed to make the surface clearer and look bit of shining, with very good corrosion resistance.

|

|

Available in different colors like metal silver, champagne, black, and the same color with mette effect.

|

|

Powder coating

|

The powdered paint is electrostatically charged and sprayed onto the part, to form a thick layer to protect the surface. With very good corrosion resistance,

|

|

Available in all kinds of colour

|

|

Wooden grain

|

New technology in finishing to form a texture look like real wood.

|

|

Available in types of wood pattern. Handtouch or film transfering are both available. Customized accepted.

|

|

Polishing

|

By buffing and chemical process to form mirror like finish, suitable for decorative application

|

|

Available in all kinds of colour

|

|

Brushed

|

By brushing and chemical process to form shining with line, suitable for decorative application

|

|

Available in all kinds of colour

|

Description:

1. Production lines

1) 5 set of melting and casting production lines

2) 25 sets of extruding production lines(from 500tons to 6800tons and meet different customer's demands)

3) 6 sets of anodizing and electrophresis production lines

4) 4 sets of German Wangner static powder coating production lines (1 set of 13 meters line)

5) 2 sets of Italian fireproof imitation wood grain and environmental protection energy saving thermal insulation cold-bridge production lines.

6) 2 heat insulation broken bridge production lines

7) 2 wiredrawing and polishing production lines

2. Quality Control

We operate the most strict quality control system, the detection is from the material, production process, to final product, and ensure the product quality and traceability.

3. Process

Die design→Die making→Smelting&alloying→QC→Extruding→Cutting→Heat Treatment→

QC→Surface treatment→QC→Welding→Packing→QC→Shipping→After Sale Service

4. Application

1) - for window and door frames

2) - for aluminum railings

3) - for building curtain glass walls

4) - for solar panel frames, Solar mounting / roofing brackets

5) - for industry assembly lines equipment.

6) - for heat sinks

7) - for LED lighting

8)- other by custom design size and dimension

5. Service

1) Supply free CAD drawings

2) Develop new moulds(die)

3) Free color samples

4) Supply any international standard color by famous powder factory like: Dupont and AkzoNobel

5) Supply customized sticker on the profiles surface

6) Customized cutting length

7) Deep processing

8) Customized package style

Our Advantages:

1. Excellent quality:

The complete quality control system is guaranteeing 100% measure up. In addition, our company fully had accredited by ISO9001: 2008.

2. Excellent equipments:

We imported the equipments from Italy and German, and the precision of the fine molds can reach 0.05mm.

3. Enormous output:

We can make customized products with different specifications with stable quality.

4. Reasonable and competitive price:

We according to customer's requirements and related reference data, after company research and development departments to study and quote a reasonable price for our customers.

5. Superior service:

We will provide customers with satisfactory products and on product packaging, logistics, warehousing and distribution link attaches great importance to, so as to enhance the level of the company as a whole, in integrated services to ensure that products in the stipulated time arrived at the customer designated destination.

6. Rich experience:

As a leading manufacturer in China, we have 22 years experience in aluminum extrusion.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!